Why Sustainable Packaging Usually Comes with a Price Tag

For too long, the assumption in sustainable packaging innovation has been: “If it’s eco-friendly, it’s expensive.” Retrofitting existing production lines is typically the first barrier, costly, time-consuming, and operationally risky.

But what if we told you the real cost of transitioning to high-performance, PFAS-free barrier coatings could be zero dollars in retrofitting?

The Cost of Retrofitting for Sustainable Coatings

At Impermea Materials, we’ve engineered solutions that integrate seamlessly into your existing coating lines—rod, gravure, flexographic, spray—without additional capital investment. No downtime. No new equipment. Just better performance, fewer compliance concerns, and sustainability without compromise.

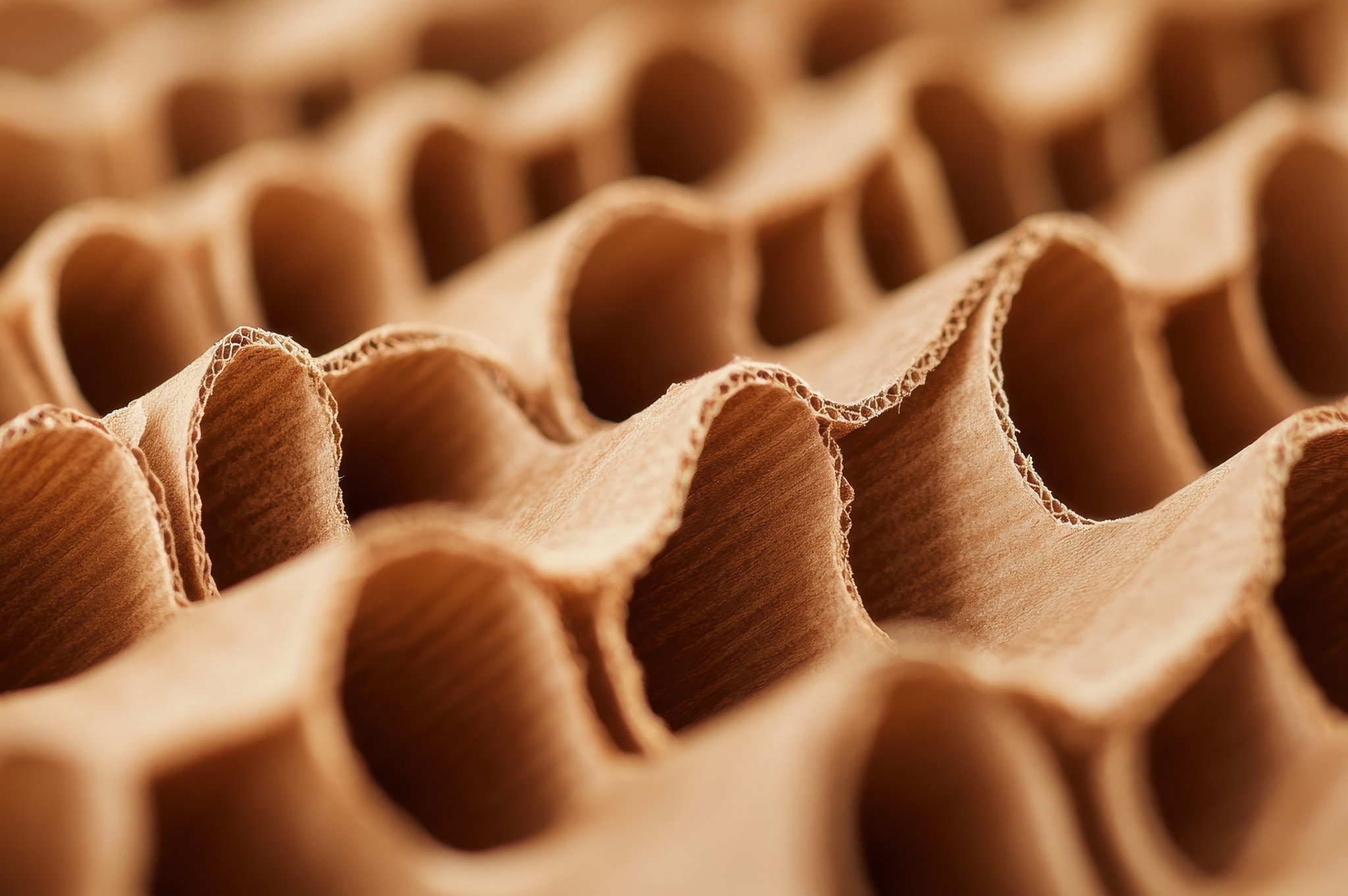

PFAS-Free, Plastic-Free Coatings That Work with Your Existing Machines

Our solutions are plug-and-play by design. Whether you're running food packaging, molded fiber, or specialty papers, Impermea’s PFAS-free, plastic-free coatings run at full production speed. No expensive retrofitting or slowdowns needed.

Products like OLEO-PAK 4100, HYDRO-PAK+MVTR 4040, and REL-PAK 4700 meet rigorous moisture, oil, and oxygen barrier standards with:

-

Low coat weights (up to 75% less than competitors)

-

FDA A-J compliance

-

Compostable, recyclable, repulpable performance

-

Compatibility with rod, flexo, and gravure application methods

Sustainable Packaging with Zero Downtime or Equipment Changes

If you're a VP of Product Innovation or Director of R&D, this isn’t just about cost, it’s about time-to-market. With Impermea, you don’t wait months for equipment adjustments or new production trials. Our team works side-by-side with you from lab to scale-up, helping you innovate faster—without compromising performance or compliance.

How Impermea Delivers Cost Savings Beyond Retrofitting

We don’t just eliminate capex. We reduce total operational costs through:

-

Lower coat weights = less material used

-

Shorter cleanup times = increased line uptime

-

No additional headcount or training required

-

Streamlined compliance = reduced regulatory risk

Traditional Coatings vs. Impermea Barrier Solutions

| Legacy Solutions | Impermea Barrier Coatings |

|---|---|

| Require equipment upgrades | Use existing machinery |

| PFAS- and plastic-based | 100% fluorine-free |

| Multi-layer application | Single-step process |

| High coat weights | Lightweight & efficient |

| Recycling challenges | Compostable & recyclable |

The Real ROI of Switching to Sustainable Materials

Switching to sustainable coatings isn’t just the right thing to do; it’s a smart financial move. With Impermea, you're not paying to go green. You're gaining performance, compliance, and consumer trust, without paying a retrofit penalty.

Ready to Switch Without the Spend?

If you're still evaluating the cost of switching to sustainable packaging, here’s your baseline: implementation cost: $0.

We custom-engineer powerful, long-lasting protection for your products without PFAS or plastic—using 75% less material than traditional coatings. Unlike most suppliers, we work directly with your converters and stay with you from initial lab testing through full production.

Together, we're setting new performance standards in packaging, textiles, and healthcare—delivering results for your business and our planet.

👉 Contact us for technical data, samples or to talk through your sustainability shift.

Your path to sustainable coatings starts now. Let's walk it together.